Yarn and carpet manufacturers use Modra’s sampling machines to efficiently create small-scale versions of their carpets for various purposes, including showcasing designs to potential clients, product development, and colour development.

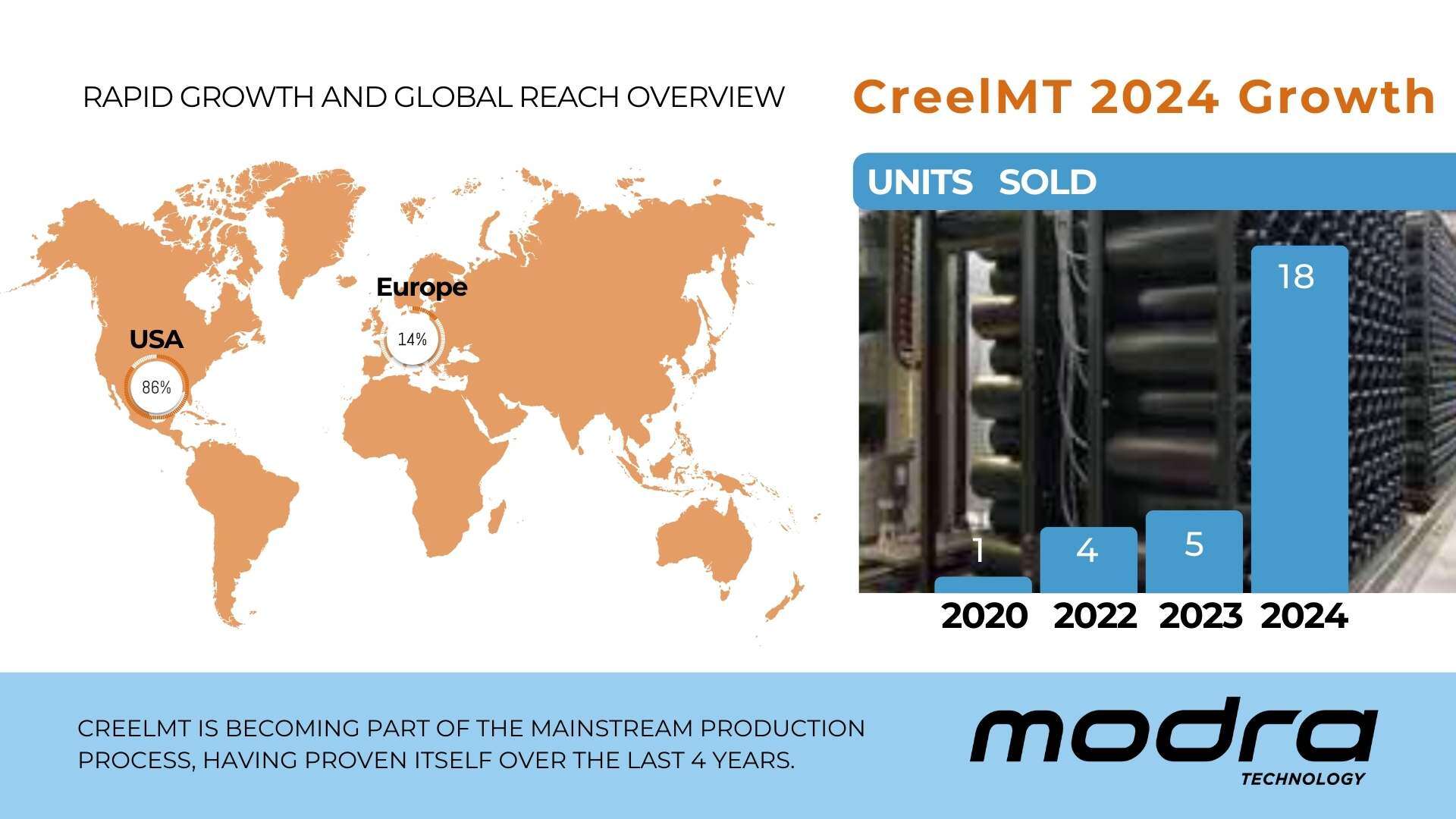

CreelMT: A Story of Rapid Growth and Global Reach

April 17, 2025

The infographic shows Modra's impressive growth and widespread adoption amongst companies seeking innovative textile solutions.

When the Sun threatens to set on an Old Industry

November 13, 2024

A factory manager’s dilemma* Fred had always taken pride in running one of the several carpet factories in town. It wasn’t glamorous work, but it was steady. He had a team that knew the ins and outs of the factory floor and could handle the intricacies of carpet manufacturing, however, things were...

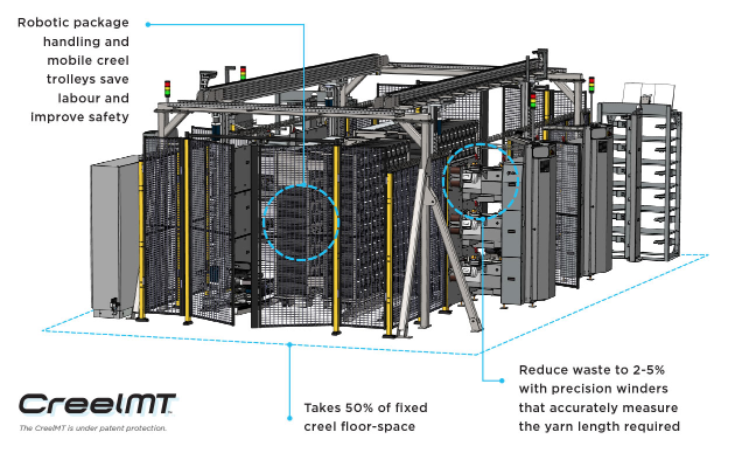

Does your business need an automated creeling system?

June 18, 2024

Do you have a tufting machine capable of variable yarn draw at each needle position? Do you want to do short product runs economically and efficiently? Do you want to expand your design options? It may not seem obvious, but a creel automation system could be exactly what you need.

The world moves to Make to Order – can the carpet industry?

October 11, 2023

Make to Stock and Make to Order are two different production strategies used by businesses to manufacture and supply products.

Modra Technology wins Leader in Digital and Advanced Technologies Award

September 13, 2023

Modra Technology was recently awarded the Leader in Digital and Advanced Technologies Award at the 2023 Victoria Manufacturing Hall of Fame Awards.

CreelMT™ wows the crowd at ITMA 2023

July 4, 2023

After four long years, ITMA was on again in June 2023. With crowds of people allowed to gather to do business, the world is moving forward at a rapid pace, with carpet manufacturers keen to upgrade, retool and redevelop their production for the growing world economy.

Rewound Yarn and OEE

May 8, 2023

Overall Equipment Effectiveness (‘OEE’) is a measure of manufacturing productivity that considers three factors: availability, performance, and quality. “Idle time”and “downtime” are two factors that can have a negative impact on OEE.

Saving on Setup and Adjustments - carpet manufacturing productivity

December 1, 2022

Of the six big losses to OEE (Overall Equipment Effectiveness), it is “Setup and Adjustments” which is by far the largest interruption to manufacturing time in the carpet manufacturers' normal operations.

Process Defects and the Carpet Manufacturer

November 11, 2022

In the continuing focus on OEE, “Process Defects” is the most curious of the six big losses for carpet manufacture.

-3.png)