Yarn and carpet manufacturers use Modra’s sampling machines to efficiently create small-scale versions of their carpets for various purposes, including showcasing designs to potential clients, product development, and colour development.

The world moves to Make to Order – can the carpet industry?

October 11, 2023

Make to Stock and Make to Order are two different production strategies used by businesses to manufacture and supply products.

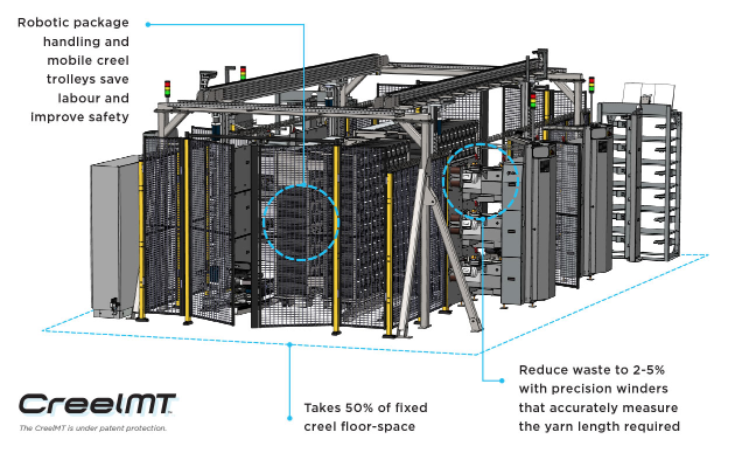

Rewound Yarn and OEE

May 8, 2023

Overall Equipment Effectiveness (‘OEE’) is a measure of manufacturing productivity that considers three factors: availability, performance, and quality. “Idle time”and “downtime” are two factors that can have a negative impact on OEE.

Saving on Setup and Adjustments - carpet manufacturing productivity

December 1, 2022

Of the six big losses to OEE (Overall Equipment Effectiveness), it is “Setup and Adjustments” which is by far the largest interruption to manufacturing time in the carpet manufacturers' normal operations.

Process Defects and the Carpet Manufacturer

November 11, 2022

In the continuing focus on OEE, “Process Defects” is the most curious of the six big losses for carpet manufacture.

We are still open

April 27, 2020

There is no doubt this is a challenging time, with so many changes coming at us all at once. We remain committed to help you – ensuring you can still access spare parts and support to keep your Modra machines working. We are doing all that we can to maintain our service levels whilst keeping staff...