Yarn and carpet manufacturers use Modra’s sampling machines to efficiently create small-scale versions of their carpets for various purposes, including showcasing designs to potential clients, product development, and colour development.

Read on to see the eight ways carpet manufacturers typically utilise carpet sampling machines.

1. Design Showcase for Customers

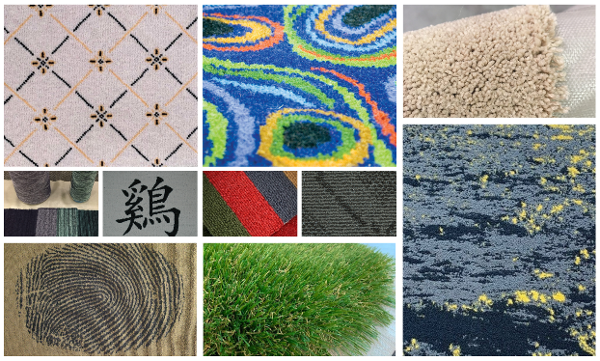

- Manufacturers use sampling machines to produce small carpet samples that showcase different designs, colours, patterns and yarns.

- These samples are then presented to potential customers, allowing them to physically see and feel the product before making purchase decisions.

2. Variety and Options for the Sales Team

- Sampling machines enable manufacturers to offer a wide variety of carpet options to clients.

- The Sales team can quickly present several or many options to clients, enhancing the range of choices available and potentially increasing sales opportunities.

3. Efficient Sample Production

- Sampling machines are designed for quick and efficient production of carpet samples rather than interrupting production by using production machinery.

- Utilising a single package of yarn per colour, allows the operator to quickly respond to customer's requests to see designs in alternative colour-ways.

4. Separation of Sampling from Production

- By using sampling machines manufacturers can separate the sampling process from the main production machines. This ensures that dedicated focus is maintained on both sampling and full-scale carpet production, avoiding disruptions in the primary manufacturing process.

5. Cost-Effective Product Development and Innovation

- Sampling machines play a crucial role in product development enabling manufacturers to experiment with new yarns, designs, and colour ranges at a relatively low cost, facilitating rapid innovation and responsiveness to market trends.

6. Quality Assurance

- Carpet and yarn manufacturers, as well as masterbatch producers, can use these machines to create samples for testing and ensuring colour consistency, performance, and overall quality before full-scale production.

7. Customer Approval Process

- The ability to produce samples with a production-quality finish allows manufacturers to streamline the customer approval process.

- By presenting carpets in a final form, manufacturers can expedite customer approval.

8. Unattended Operation for Efficiency

- Modra’s carpet sampling machines are designed to run unattended once set up.

- This enhances operational efficiency and reduces the need for constant supervision.

In summary, Modra’s sampling machines are a versatile tool for manufacturers, serving purposes ranging from sales and marketing to product development, quality assurance, and overall production efficiency. Contact Modra today.