Of the six big losses to OEE (Overall Equipment Effectiveness), it is “Setup and Adjustments” which is by far the largest interruption to manufacturing time in the carpet manufacturers' normal operations.

Obviously, a major breakdown can be much worse but in normal operation “set up” time is something that is continuous and often accepted as a significant stop to operations.

Setup and Adjustments account for any significant periods of time when your manufacturing machines or equipment are not running due to adjustments or needing to be set up for a job.

These breaks in production are scheduled, and it is easy for carpet manufacturers to think of these setup and adjustment periods as “uncontrollable” or “acceptable” in terms of the amount of time and impact. But this really isn’t the case. In fact, it is the concentration on setup in which real OEE advancement can be made.

Tufting machine and creel set-up, in particular, in-creel splicing of individual ends when switching from the running yarn package to the next yarn package, requires a considerable amount of time in both manual labour and tufting machine downtime.

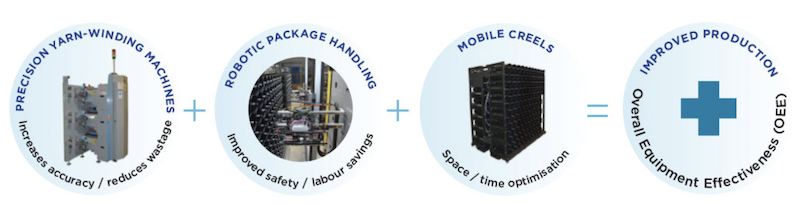

Robotic package handling, beam splicing and mobile creel trolleys

The CreelMT, used in conjunction with a beam splicer can reduce this downtime by 50%. With the CreelMT system, a precision wound package of yarn is loaded into a mobile creel trolley by a robotic package handler. The full mobile creel trolley is then beam spliced to the tufting machine, up to 110 ends at a time. This can significantly reduce the stoppage time of the tufting machine.

How it works

With the CreelMT you will typically have three sets of trolleys in process at any point in time.

- One set of trolleys being prepared.

- One set of trolleys feeding the tufting machine.

- One set of trolleys on standby, ready to be moved into place to feed the tufting machine for the next carpet run.

Once one production run is finished the next set of mobile creel trolleys is moved into place and beam spliced to the tufting machine. A skilled operator could complete the beam splicing in around 5 minutes per 110 ends, meaning beam splicing 1,000 needle positions, for example, could take as little as 45 minutes.

See the CreelMT in action:

Adding a CreelMT into your production process, replacing your traditional creel setup, can have the single biggest impact on your OEE – increasing it by 15% or more.

Set up is not the only benefit - contact us to learn more

The CreelMT is not only a solution to the setup process but it can help reduce lost time due to equipment failure and adjustment time. Please have a chat with us about all the different solutions that might help your business.